Wood Properties and Selecting the Right Timber

Wood is the fibrous substance of a tree. It’s the very thing that provides support for the tree so that it will stay stable and grow. While some people tend to use the term “wood” to mean timber, these two terms are not the same. In Australia, New Zealand, and the UK, timber is sawn wood and processed wood products. They are used for home construction, decking, cladding, and making furniture pieces, such as pool, billiard, and snooker tables.

Timber (also called lumber in the USA and Canada) can either be softwood or hardwood, which we will talk about later on in this article. Each type has its own properties and aesthetic appeal.

Raw wood processing is performed through an intensive agreement before it can be utilised. Moisture and other factors are released to create a seasoned wood. From there, further developments will allow the production of the ultimate timber ideal for furnishing designs. Let’s dive into this process from understanding the beginnings of wood until it is ready for furniture-making.

How Trees Grow

Humans and animals grow by increasing the size of the muscles, bones, skin, and other parts of the body. Interestingly, trees do not develop this way; rather, they produce new cells in some places of cell division known as meristems. These zones have intense activities where new cells form and expand.

Trees grow taller because they have meristems located at the ends of their branch called apical meristems. They are responsible for root growth, too where roots expand at their tips.

Most trees have six organs, namely:

- Leaves

- Stems

- Flowers

- Fruits

- Seeds

- Roots

When the tree grows, it increases in size and its vegetative structures, which are the leaves, roots, and stems. Trees thrive when they get plenty of sunlight, carbon dioxide, minerals, and water. These necessities come together to allow trees to produce sugars, which are the building blocks of their growth.

Unlike humans and animals, trees do not feed themselves through their mouths. Instead, they make their own food using raw materials from the soil and air, which is a process known as photosynthesis. It occurs in the leaves, which have numerous tiny pores where air enters. Water and chlorophyll combine with air to produce sugar, specifically glucose. It will then be distributed to the sap stream directly to the parts where the tree grows. Glucose will then be converted into cellulose, starch, and other complex carbohydrates.

The Stem

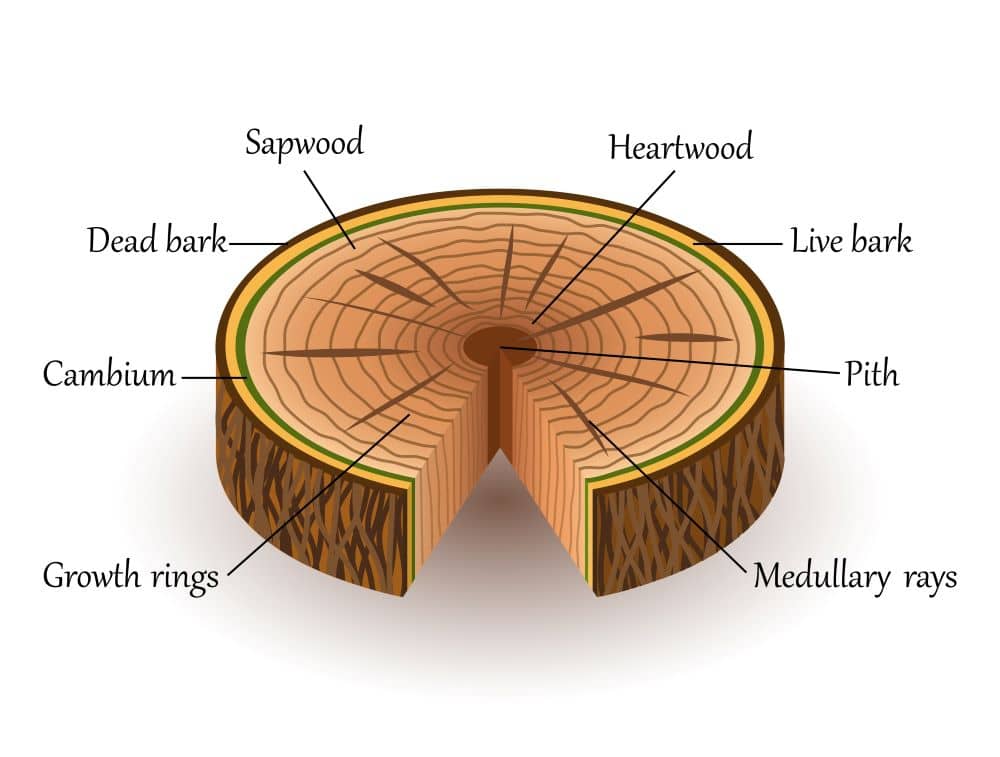

A tree’s stem has six parts:

- Pith, which is the softcore near the centre of the stem

- Sapwood, which has the responsibility to carry water and nutrients from the roots

- Heartwood, which pertains to converted inner sapwood because of its inactivity

- Phloem, which is where the inner bark is formed

- Cambium, which is a thin, slimy layer right under the phloem with cells multiplying to create new phloem tissue

- Outer bark, which is the dead material that protects the stem so it will not get damaged

The stem of the tree is the primary source of timber, particularly these two parts: sapwood and heartwood. Sapwood is used to identify if the timber is from softwood or hardwood species.

Hardwood vs Softwood Structure

Generally, the sapwood band is wider in softwood species while hardwoods have narrower bands. Most of the time, timber from hardwood is re-sawn to remove the sapwood. This process is necessary to ensure that insects will not attack the timber product.

In comparison, softwoods are not as susceptible to insect attacks. They perform better even when they have been completely cut from the sapwood. These softwoods typically have no issues with preservatives, and they even dry evenly.

The structure of these two species can help explain why. Let us first talk about hardwood in which Western Australia is home to some of the best hardwoods in the world.

Contemporary pool table made from Jarrah timber.

Hardwoods are botanically referred to as angiosperms whose literal meaning is “covered seeds.” This characteristic relates to their seeds contained in flowers or gumnuts (fruits of a eucalyptus tree). A common misconception about hardwoods is that they are “hard.” In reality, not all from this species are hard, such as balsa, which is very soft.

Other examples of hardwoods are:

- Teak

- Mahogany

- Oak

- Alnus

- Rosewood

Many hardwoods have two cell types running vertically. The sap is spread upwards in the vessels or pores. The fibres determine how strong the tree is. With the bulk of the wood mostly made of thick cell walls, hardwoods are solid and durable.

Now, let us discuss what softwoods are. Softwoods are referred to as gymnosperms – the exact opposite of angiosperms since they are “uncovered seeds.” You will find the seeds in cones, which allow them to germinate when the wind blows them away.

Commercially, softwood timber originates from conifer trees. These trees are easy to distinguish because they have a conical shape with leaves that resemble needles. Conifers are mostly evergreens, which means that they do not lose their leaves during the autumn season.

Softwoods do not have pores or vessels in their structure. The woody tissue has tracheids, which are long narrow cells that move the sap to the roots and branches. These cells also add to the strength of the timber.

Some examples of softwood trees are:

- Cedar

- Pine

- Cypress

- Fir

To make identification easier, hardwoods are timbers with pores while those without pores are softwoods.

The following are species commonly used in furniture-making:

- Alpine ash (hardwood)

- Australian cedar (softwood)

- Balsa wood (hardwood)

- Baltic pine (softwood)

- Beech (hardwood)

Blackbutt (hardwood)

- Bluegum (hardwood)

- Brush box (hardwood)

- Cypress pine (softwood)

- Hoop pine (softwood)

- Ironbark (hardwood)

- Jarrah (hardwood)

- Kauri pine (softwood)

- Meranti (hardwood)

- Oregon or Douglas fir (softwood)

- Poplar (hardwood)

- Radiata pine (softwood)

- Rosewood (hardwood)

- Silky oak (hardwood)

- Spotted gum (hardwood)

- Spruce pine fir (softwood)

- Tallowwood (hardwood)

- Western hemlock (softwood)

- Western red cedar (softwood)

It does seem that the majority of timber used for furniture-making is hardwood. However, it does not mean that softwoods are inferior. They have excellent characteristics that make them a good choice for construction and woodworking. For example, since softwoods do not have vessels or pores, they can quickly absorb glue when you stick parts on them or have the surface laminated. You can see the difference as you develop a fine product.

When sorting timber, check that the plank has solid wood. Both hardwoods and softwoods are solid wood, but there is a chance you have a decayed wood. Solid woods are easily workable. Carpenters can nail, screw, or hammer them without fearing any effect on grains. If there are interlocked or spiralled grains, they should not be used to construct furniture.

Solid wood can be identified through the following:

- Fibres are aligned, straight, and firm

- Ring direction match the edge

If you can’t decide, you can sand the wood to reveal any stuffed chips or fillers.

Other Facts to Know About

Growth Rings

They are also important when selecting the timber for your project. Growth rings are called springwood or earlywood, which is a portion of fast-growing tissue that appears in timbers with lighter colours. These rings occur when the trees grow rapidly because they receive ample sunlight and water at an ideal temperature.

When water supply becomes scarce, and the temperatures are colder. That’s when trees grow slower, and they develop rings called latewood or summerwood. Some species come with separate growth rings called annual rings. They’re usually present in softwoods, but certain hardwoods found in colder climates have these annual rings, as well. Often, growth rings are highly prized because they make the timber more distinct.

On the topic of colours and appearance, darker shades of timber are usually chosen over lighter ones. Light-coloured timbers are often viewed as weaker. Darker timbers can help cover different types of exquisite furniture, giving a more vintage look.

Reaction Wood

Trees try to absorb as much sunlight as possible, which is why they grow vertically. However, some choose one side to reach for sunlight. Others have to withstand heavy wind blows that continue to stress them, causing them to sway to that direction.

Wood that counteracts the environmental stressors mentioned is called reaction wood. This characteristic is normally seen in branches, which may have visible changes in angles. When processed, timber will have knots. Unfortunately, reaction wood is not as strong as regular wood. When treated, it tends to shrink more prominently as it dries.

Reaction wood in softwood and hardwood species commonly occur as described below:

- Softwoods have their reaction wood on the underside of the tension where the trees lean. Since the wood tissue receives pressure on top of it, the reaction wood is called compression wood. It usually has a darker colour compared to the other parts of the wood. When cut or sanded, it generates a fuzzy finish.

- Reaction wood in hardwoods happens on the upper side of a lean. The tree is pulled upwards from its crown, causing it to be under tension. It is why this reaction of wood is called tension wood. Just like softwoods, it has a fuzzy finish when cut or sanded. However, this reaction of wood cannot handle the pressure, so it collapses when dried.

Reaction wood is a useful measurement of wood strength. It shows how much pressure the wood can withstand from different locations. Timber should be capable of retaining its shape even after treatments or production procedures. Wood grains should have a uniform direction.

Woodworking results can be badly affected after misaligned hammering. However, if the wood is strong enough, loads and mistakes will not lead to breakage and cracks.

Durability

It’s not surprising that many think hardwoods are more durable than softwoods. Perhaps it has something to do with the name. Nevertheless, the durability of timber depends on different factors. Durability pertains to the life expectancy of timber, particularly when it is exposed to creatures or insects that might attack it.

Durability is measured by testing the heartwood of timber. The Australian Standard (AS) 5604 determines the durability ratings of different types of timbers, which are classified as:

- In-ground durability

- Above-ground durability

Both factors are considered when testing the life expectancy of timber. Above-ground timber usually lasts longer since in-ground timber is in direct contact with environmental elements, such as fungal decay, insect attacks, and moisture.

Here are samples of the natural durability of species without treatment:

- Alpine Ash: 0-5 years in-ground and 0-7 years above-ground

- Blackbutt: 15-25 years in-ground and greater than 40 years above-ground

- Douglas Fir: 0-5 years in-ground and 0-7 years above-ground

- Jarrah: 15-25 years in-ground and 15-40 years above-ground

- Karri: 5-15 years in-ground and 15-40 years above-ground

- Red Mahogany: 15-25 years in-ground and greater than 40 years above-ground

- Hoop Pine: 0-5 years in-ground and 0-7 years above-ground

- Radiata Pine: 0-5 years in-ground and 0-7 years above-ground

- Turpentine: 5-15 years in-ground and 15-40 years above-ground

Wood for furniture-making should be incredibly durable. The construction process includes frequent hammering, exposing the timber to shocks and vibrations. Therefore, it should be able to withstand these tests. Select timbers with high-rated durability, so that they are almost unbreakable. You can even bend them a little without worrying about tearing the planks up while fixing and adjusting the furniture parts.

Density

Another factor that affects choice in timber selection is density, which is the weight or mass in a given volume. It’s measured in kilograms per cubic metre ((kg/m3). Why should you consider timber density? The answer is simple: denser means stronger. It’s because the cell walls are often thicker.

However, density may also be affected by water, oils, and resins present in the wood, making it heavier than it should be. It does not mean this timber is strong, though, which is why measuring green density (GD) is not a good idea. GD is the wood density when the tree is felled. Therefore, it still contains water, which can make it appear more robust than it actually is.

Air-dry density (ADD) is a better measurement, which tells you the density of wood with 12% moisture. Moisture content does not change, so it is a good indicator. Another way to measure density is through basic density (BD), which means wood does not contain water.

It’s crucial to opt for dense timber as much as possible. The thicker it is, the higher the chance of possessing fire resistant capabilities. Dense timbers have natural insulation, making them a suitable choice for residential and commercial applications. Hardwoods are generally preferred over softwoods, especially for kitchen cabinets, washroom dressers, and flooring. Softwoods, unfortunately, are generally weak in resisting fires.

Hardwoods are typically heavier than softwoods. It is why hardwoods are considered the best option for structural and large furniture pieces, including pool tables.

Wood-Destroying Organisms

Trees have a natural defence against organisms that eat wood. However, once they have been felled and resawn, timber products have no known resistance against most creatures.

Some of the organisms to watch out for are:

- Fungi: Fungal attack happens when the moisture content is at least 20%. When wood receives enough oxygen and offers a suitable temperature range, fungi can thrive. The three main types of fungi are brown, white, and soft rot. They all eat the cell walls, leading to wood fibre breaking and crumbling. Fungi can also disfigure wood, which leads to discolouration when left untreated. They leave stains, such as blue stain, which is common in softwood sawlogs.

- Borers: Beetles or borers look for wood, which they use as shelters or eat as their food. Borers are a severe problem because they affect the strength of the timber. Some examples of borers are lyctid borers (powder post beetles) that attack the sapwood of hardwoods and anobium borers (furniture beetles) that love damp and old furniture, such as unrestored pool tables.

- Termites: Australia has approximately 300 termite species. Thankfully, only a dozen target buildings. They create shelter tubes covered in mud over the foundations and sometimes in the walls. They aim to get to the subfloor timbers, which they can destroy if you leave the problem alone.

The best timber for furniture-making should be resistant against all these organisms. While no timber is perfect and all have some form of susceptibility, you can help it from creature attacks. High-quality hardwood and softwood can naturally fight termites. If you have budget constraints, you can still protect the timbers by polishing or coating them to keep attacks at bay.

The Process of Drying Wood

Logs contain a lot of water. After cutting, free water is allowed to evaporate until almost all the moisture is gone.

There are two main ways to dry wood, which are:

- Air drying: When air dried, timber should not touch the ground. Each piece should stay clear of one another so air can help remove surface moisture. It does take a long time for this method to finish. One-inch or 25mm thick hardwoods require about a year to reach equilibrium moisture content (EMC). It pertains to moisture content similar to the surrounding air. Note that it is not possible to have zero moisture content when air-dried. The reason is that air always has some moisture.

- Kiln drying: This drying method uses kilns, which have ventilation systems. They enable controls for humidity and heat so that that wood will dry faster. Some hardwoods tend to dry slowly, making this method a better option than air drying. Kiln drying can dry wood with 30% moisture to 12% in just several days. The downside is that high-temperature kilns can lead to drying stresses. Hardwoods can be pre-steamed before the process to reduce breaking or collapsing. Plantation softwoods, including radiata pines, are best exposed to high-temperature kilns. The species can be dried within a matter of hours.

As an aftereffect of drying timber or draining its moisture content, wood can shrink and move. The shrinkage rates differ depending on the material, its width, length, and thickness. How it is cut can also affect how much it moves. For example, if you have a backsawn board, it will reduce in size twice as much as a quartersawn board. However, its edge will not shrink as much and usually just half of the face.

Wood is an organic substance so that water can permeate through its pores over time. Moisture can shorten the lifespan of timber due to decay. Therefore, it is a good idea to choose wood that has significant non-permeable qualities.

Timber decay is a common problem, which is due to water, infestation, and other damage. Dense wood with close knot grains can fight off different types of decay. Often, hardwood is less prone to decay compared to softwoods. Therefore, they are a better choice when creating outdoor pieces of furniture.

Quedos has been in the industry for a long time. We understand the various types of timber and which ones are best for our pool tables. We use hardwoods, such as Jarrah, Marri, Blackbutt, and Blackwood, which have proven their durability, hardness, and sturdiness, and longevity throughout the years. Check out our pool table collection here or contact us on 1800 147 868 for free.

Blackbutt (hardwood)

Blackbutt (hardwood)